Proper process planning is one of the most undervalued aspects in the cannabis space. That might sound like a bold statement, but it’s true. In my experience, I’ve worked with a lot of operators who didn’t plan their process correctly and ended up overspending on equipment that either doesn’t work for their operation or isn’t actually needed.

A lot of these mistakes can be avoided with something as simple as a spreadsheet. Every time a client approaches me about buying a machine, I ask two basic questions:

How much do you want to produce in a month?

How many shifts are you running?

With just those two questions, I can calculate everything else in the process.

NOTE: Doing several scenarios and doing good design margins, can get remarkably accurate results. I suggest doing several variations of your calculations with different inputs for each assumption.This will reveal the real sensitivities of the system you are currently operating and it will give you a deeper understanding of what will help you achieve a successful outcome. If you’re interested in a further breakdown comment below.

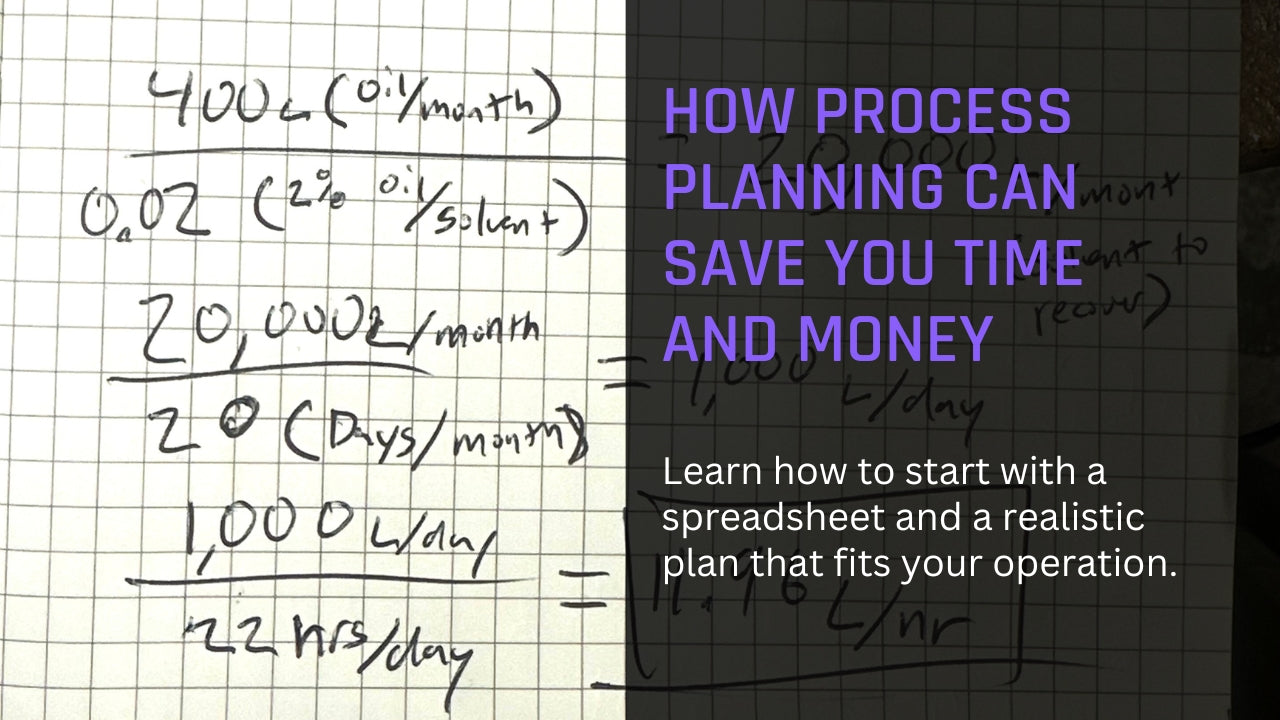

Here’s a common scenario I see in the field. A client wants to scale up their process and produce 400 liters of distillate per month, and is running a spec’d “30GPH” (Gallon Per Hour) solvent recovery. They’re running their solvent recovery around the clock, but somehow it’s still a bottle neck in their lab. To try and reach their goal, the client thinks they need to shop for a 60GPH recovery system. This is where proper process planning comes in to determine whether or not the client actually needs to invest in a unit that makes double the yield.

Let’s start with the worst case scenario:

-

We will assume a 2% oil to ethanol solution

-

Running 22hours a day

-

20 days a month

After doing the math (see equation above) this would require the recovery of 12GPH to meet the target of 400 liters of distillate per month.This means that the “30GPH” is under performing and is actually producing less than 12GPH.

By doing the math, the conclusion is the opposite of what was originally assumed, the client would need a system that is much SMALLER, as long as it performs according to specification (admittedly a rare find in this industry), this demonstrates that reliability is more important than what was originally claimed.

Once that distinction is clear, better decisions become possible. For example, if the same client wants to move to a single-shift operation, we can account for startup, cleanup, and maintenance and assume roughly six productive hours per day over 20 days per month. To maintain the same output of 400 liters per month under those constraints, the process would now require about 44 GPH of real solvent recovery.

At that point, a system similar to the original “30 GPH” unit would need to claim something closer to “120 GPH” to reliably deliver 44 GPH in practice. On the other hand, a truly reliable system that consistently delivers 12 GPH and can run overnight without supervision may outperform a system with ten times the advertised capacity. This is why performance consistency matters far more than the number on the spec sheet.

There’s another major advantage to good process planning. By applying basic thermodynamics, it’s often possible to estimate exactly how fast a solvent recovery system can run by looking at heater capacity, chiller capacity, or other fundamental constraints in the process. These first-principles limits tend to be far more reliable than manufacturer claims and provide a clearer picture of what a system can realistically achieve.

When it comes to process planning, bigger doesn’t always mean better. What matters more is buying a system that’s reliable and actually fits your operation. The best place to start is with a spreadsheet and a realistic plan—not by immediately purchasing whatever looks good on the market. And if you need help with that process, I offer consultations for labs to make sure they’re on the right track before they invest.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.